Project Description

Effiziente Automatisierung mit einem kollaborierenden Roboter – Übersicht

Die FME Feinmechanik AG vertraut auf zwei kollaborierende Roboter von Universal Robots, auf den UR5 und den UR10. Mit den Robotern soll eine höhere Flexibilität in der Produktion erreicht werden. Dazu wurde im Unternehmen jetzt die Schichtarbeit beendet. Insgesamt sind die Produktionsprozesse des Unternehmens durch die Automatisierung erheblich effizienter geworden.

Die Herausforderung im Unternehmen

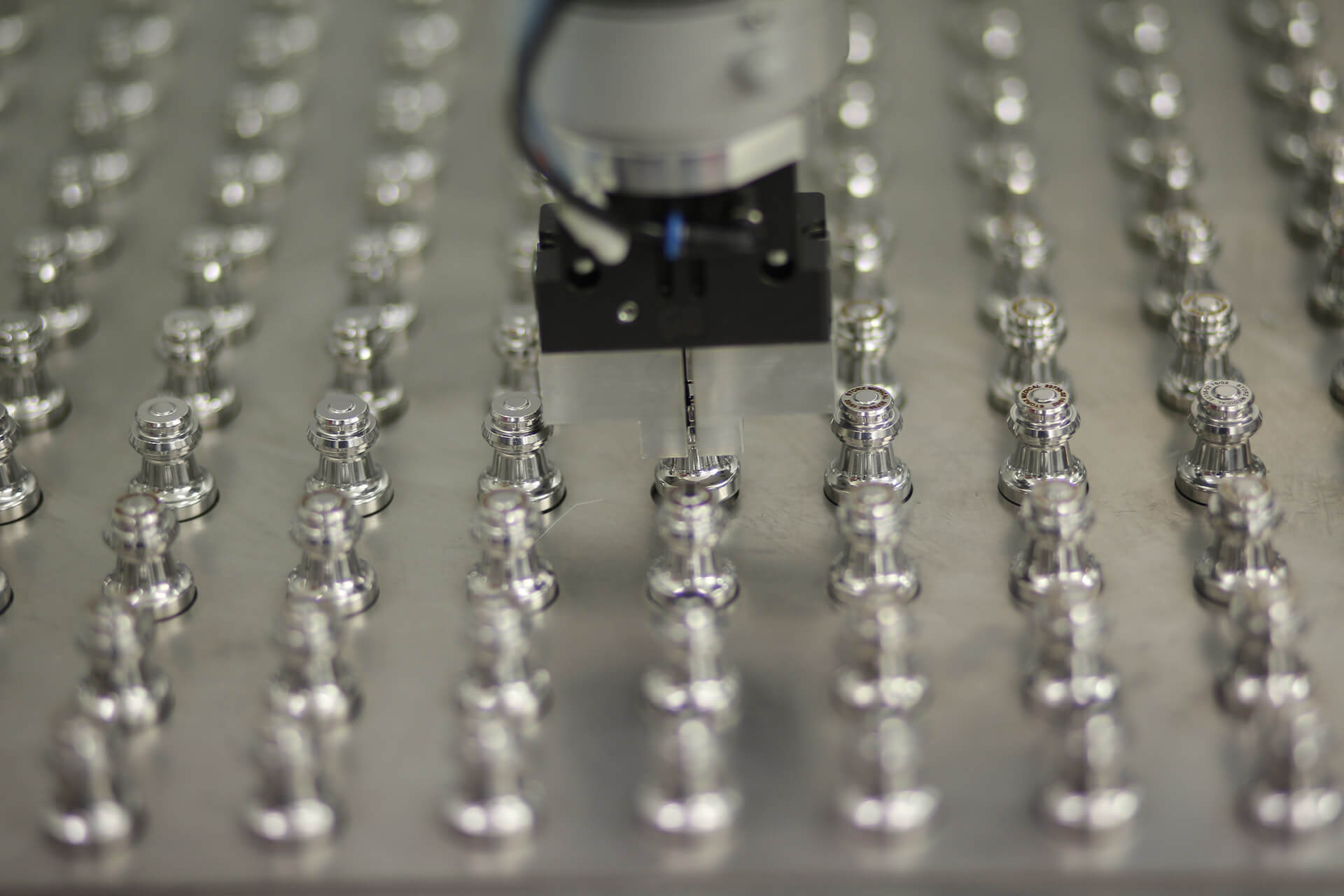

Die FME Feinmechanik AG ist ein Hersteller von kleinen, feinmechanischen Bauteilen für die Medizintechnik. Sie werden präzisionsgefertigt. Deshalb ist eine Automationslösung, die höchste Flexibilität bietet und mit bester Qualität produziert.

Ein Einsatz von Industrierobotern wurde vom Unternehmen bisher nicht in Betracht gezogen, da sie als schwerfällig und unbeweglich gelten. Diese Einschätzung ist sehr wichtig, da einige Produktionsteile extrem dünnwandig sind, oft sind sie nur halb so dick, wie ein menschliches Haar. Dazu liegen die Produktionsmengen zwischen 50-10000 Stück. Eine aufwändige Programmierung von Industrierobotern ist deshalb nicht rentabel.

Diese Einschätzung musste die FME Feinmechanik AG jedoch überdenken. Die Kosten stiegen immer mehr an, Mitarbeiter mit monotonen Aufgaben wurden unzufriedener, die Nachfrage nach Produkten und auch die Produktemengen stiegen an. Angesichts dieser Aussichten musste eine neue Lösung her.

- Höchste Flexibilität

- Höchste Präzision

Sehr feine Produktionsteile

Kostendruck

Hohe Nachfrage

„Die Roboterarme von Universal Robots haben meine Erwartungen weit übertroffen.”

Die Lösung von Universal Robots

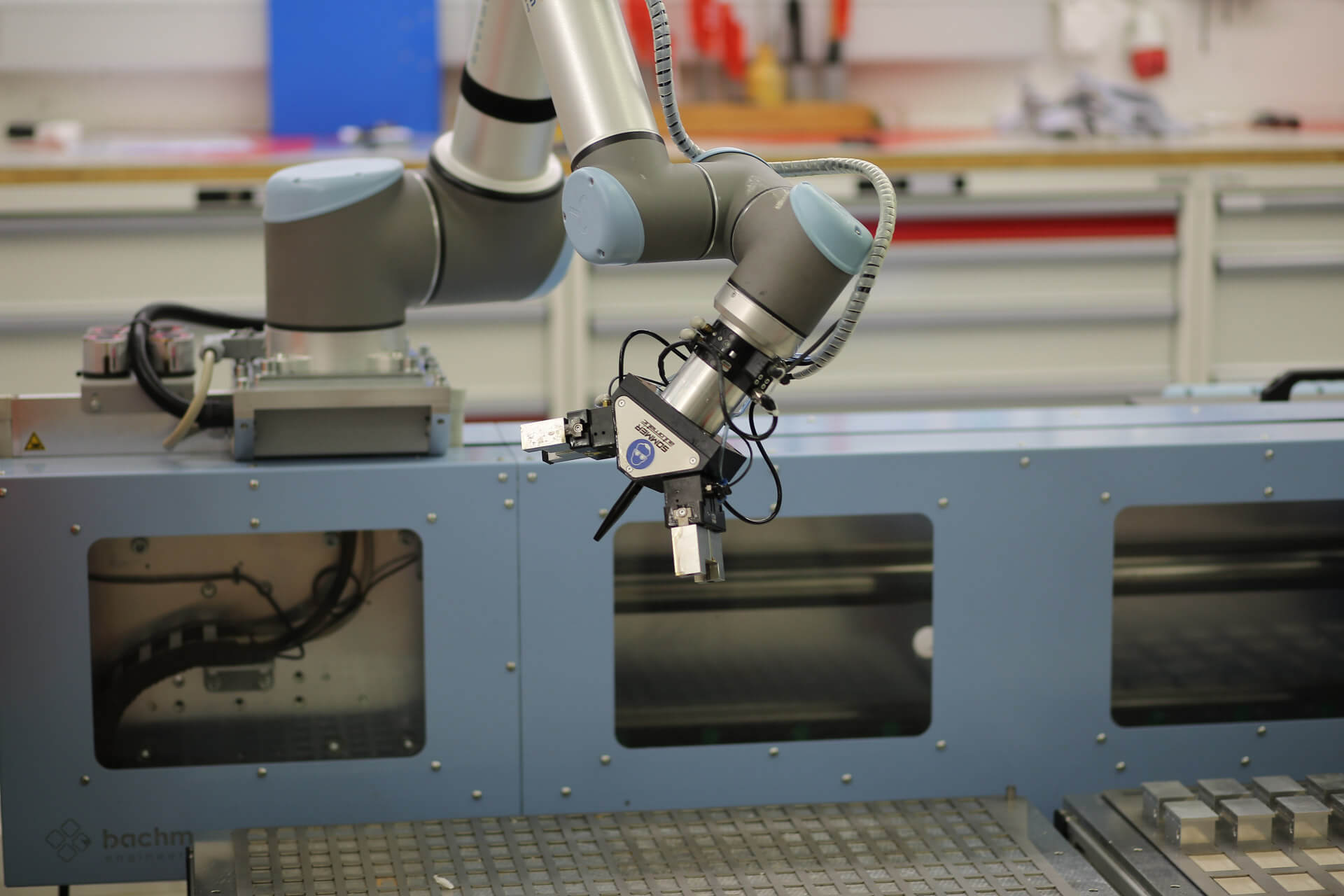

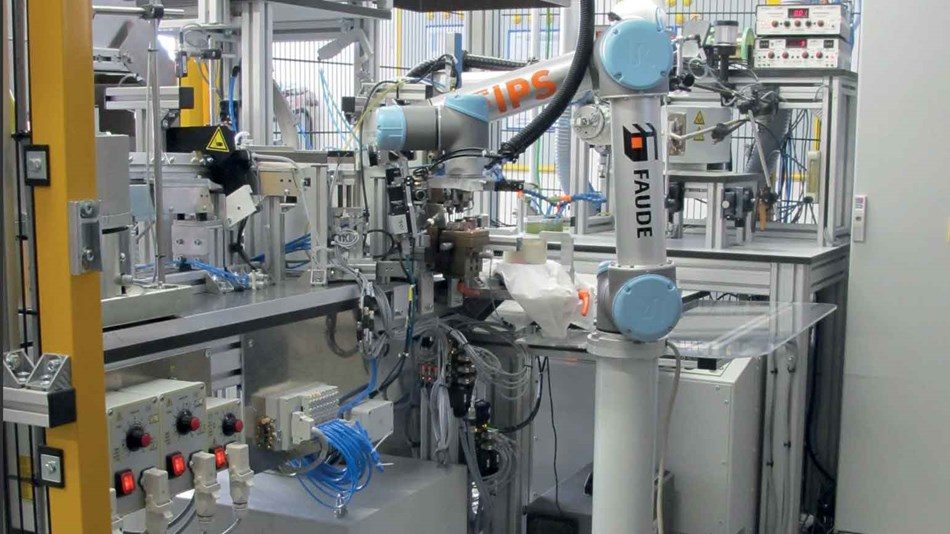

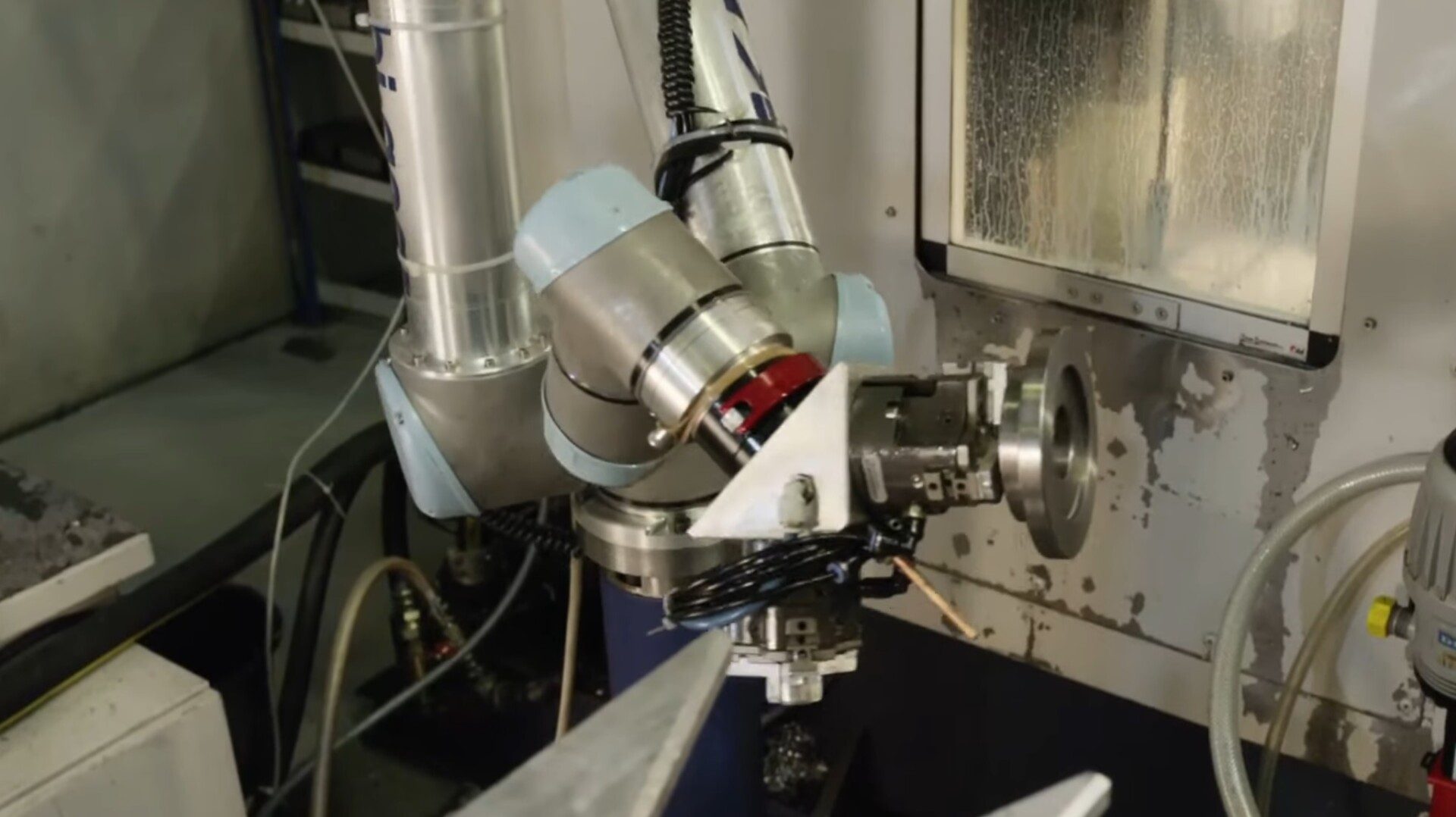

Bei der Beratung wurde der FME Feinmechanik AG die Lösung von Universal Robots empfohlen. Ein stationäres und automatisiertes System, das eine effiziente und ununterbrochene Produktion von hohem Standard gewährleisten kann. In der Lösung kann ein UR5 Roboter zwei gegenüberstehende Maschinen bedienen, während ein UR10 Roboter zur Zuführung eingesetzt werden. Er positioniert das nächste Bauteil nach einem Signal des UR5 Roboters.

Der Geschäftsführer, Marco Bortolan ist sehr überzeugt von dieser Lösung: „Die Roboterarme von Universal Robots haben meine Erwartungen weit übertroffen. Die Verbindung von Flexibilität und einfacher Programmierung sowie die Tatsache, dass die Roboter ohne eine platzraubende Schutzumhausung direkt mit meinen Mitarbeitern zusammenarbeiten können, waren entscheidende Faktoren, die mich davon überzeugt haben, in diese Technologie zu investieren und die entsprechenden Veränderungen in unserem Unternehmen einzuführen. Dank dieses Erfolgs und unserer positiven Erfahrung kann ich mir durchaus vorstellen, in Zukunft noch weitere Roboter einzusetzen.”

Laut Marco Bortolan herrscht meist das Vorurteil, dass Roboter Arbeitsplätze bedrohen würden. Bei der FME Feinmechanik AG war das nicht der Fall. Das Team musste sogar vergrössert werden, da die Produktivität gesteigert werden konnte.