Project Description

Automation in confined working environments- The result

Due to the increase in order volume, Multi-Wing CZ had to find a way to make better use of the limited space. The existing production was to be increased despite the limited space. Production costs fell by 10-20% with the use of a UR5, which means a saving of 7,000 euros per year. At the same time, there was additional production capacity.

The challenge in the company

In order for Multi-Wing to meet the increasing demand, part of the production had to be automated. The company manufactures axial fan solutions for ventilation systems and wants to play a bigger role in the global market.

The limited space meant that a conventional robot was out of the question, as this would require a safety enclosure. From the outset, the company wanted a small and cost-effective robot that was also flexible.

- Competitive pressure

- Little space

Cost pressure

"Compared to competitor robots, the purchase of the UR5 meant a faster return on investment. We had no problems with this flexible, fast and cost-effective solution, which has opened up numerous savings opportunities and new perspectives for us. We are delighted with the Universal Robots technology."

The Universal Robots solution

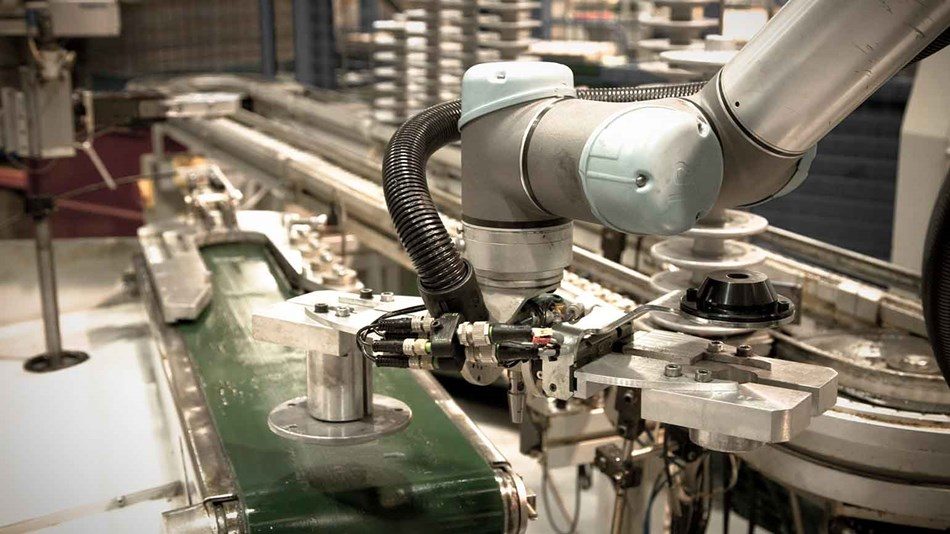

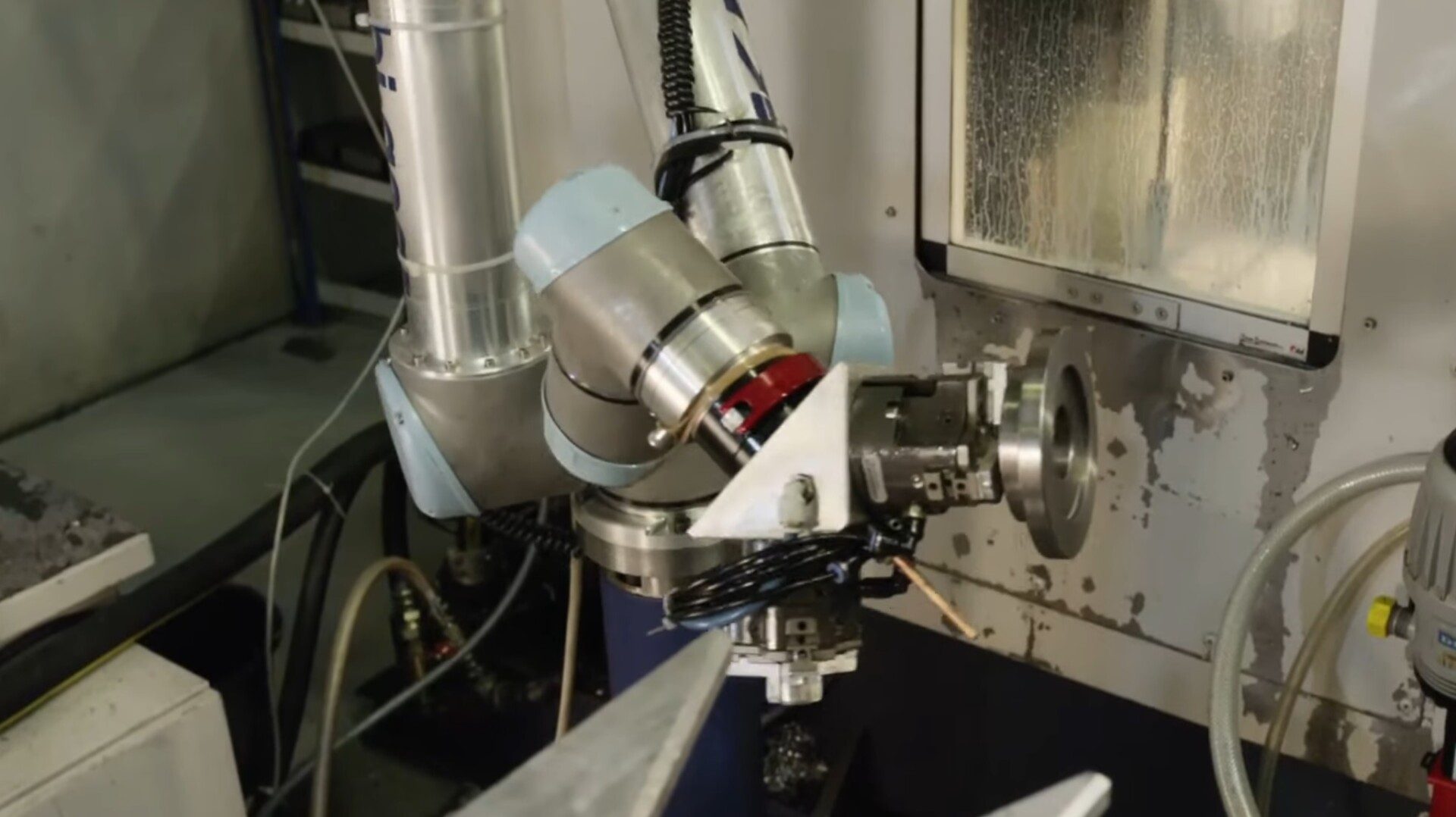

The company opted for a UR5 robot for the automatic production machine that installs aluminum pieces in hubs. Fully automated, the robot arm places the unfinished castings in the machine, removes them after processing and transfers them to a broaching machine, which mills a groove in them. The cobot does all of this without a safety enclosure. Thanks to the effective use of space, even more space could be created in the limited environment.

The use of the cobot increased the feeding speed by 70%.