Project Description

The result at a glance

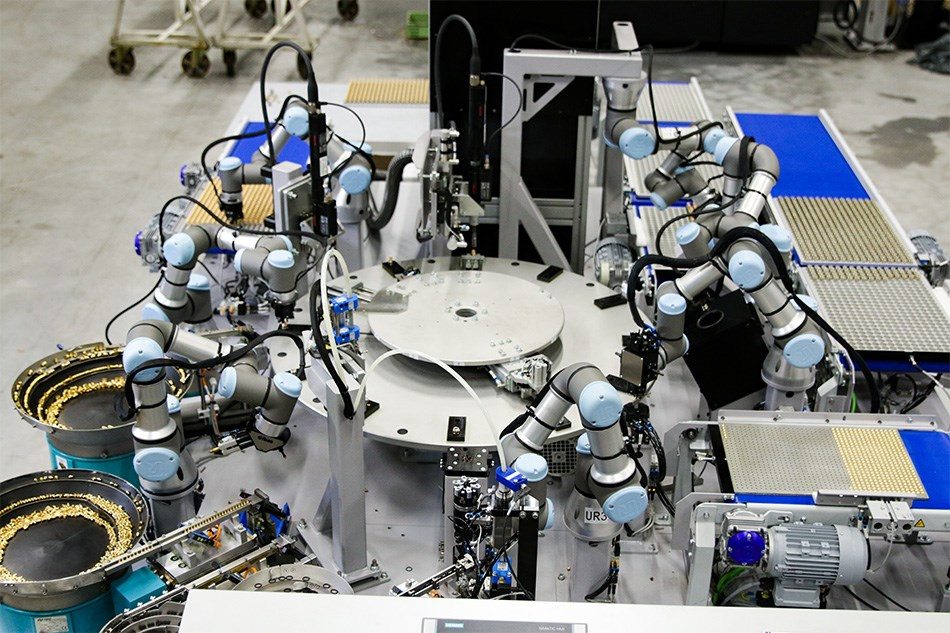

Fluidics Instruments B.V. uses a total of 12 collaborative robots (cobots) from Universal Robots in its production. As a result, production and turnover can be constantly increased despite a shortage of skilled workers. The manufacturer of oil burner components is on the right track.

The challenge in the company

As with many other companies in various industries, Fluidics is constantly faced with an important challenge: the order situation is variable. There are small productions that are only in the range for a short time, but there are also products that are manufactured in very large batch sizes. As a result, the use of the machines varies greatly.

In addition, the shortage of skilled workers also plays a major role in the Netherlands.

Fluidics therefore tried to outsource production. However, this did not produce the desired quality. Another solution had to be considered.

Variable order situation

Skills shortage

Cost pressure

Highest quality required

Outsourcing not possible

The Universal Robots solution

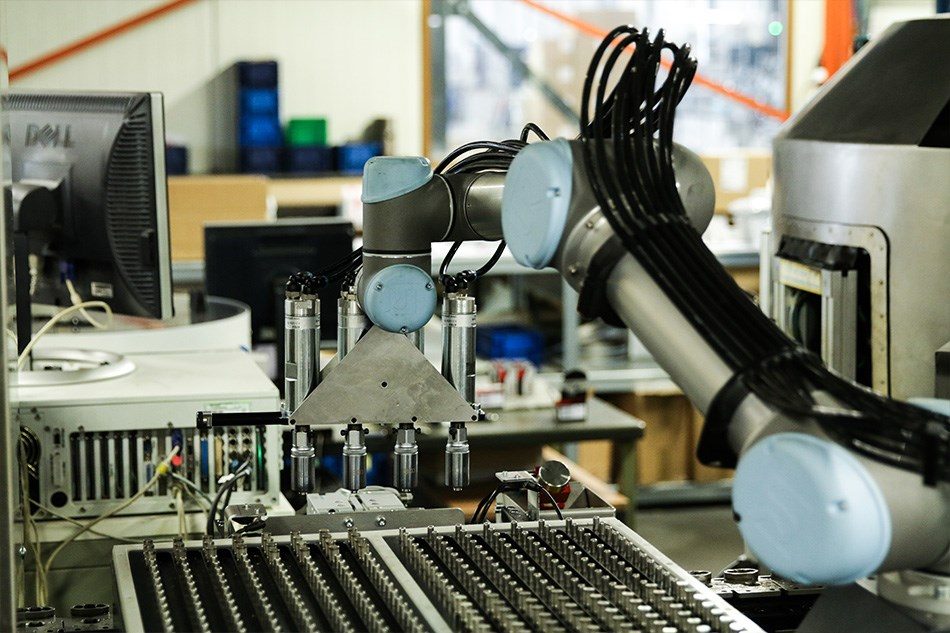

The company actually found a suitable solution: automating production. The company relies on a number of machines and robots, including the collaborative robots from Universal Robots.

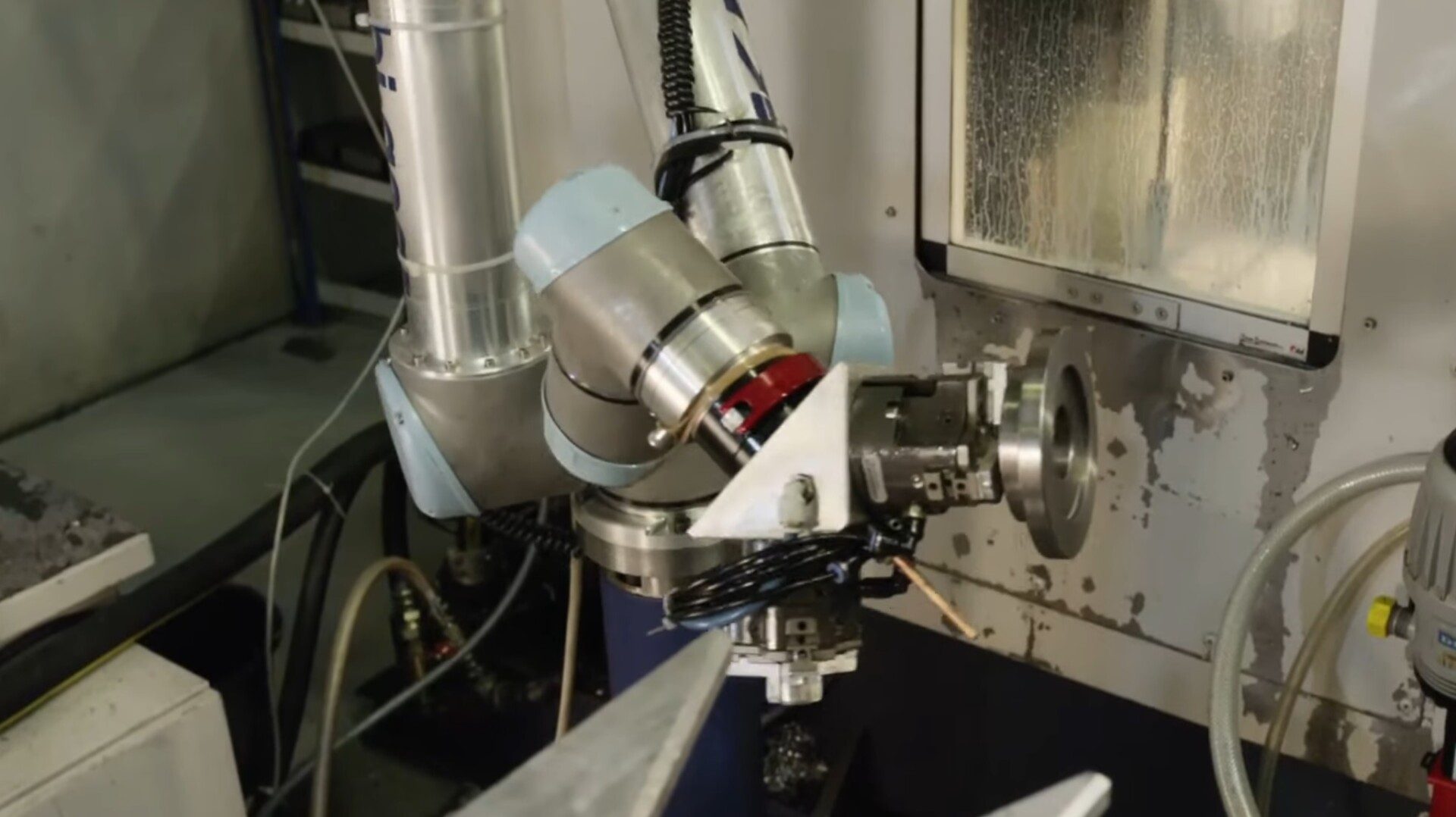

An important feature of the Cobot is its flexibility in use. This enables Fluidics to respond optimally to the variable order situation. If a CNC machine is temporarily out of operation, the cobot can easily be assigned to a new task. In this case, this is usually the loading of another machine. Two UR5 and one UR10 were mounted on mobile workstations for such variable applications.

"With the help of our 12 UR robots, we are able to offer our customers the usual 'Made in the Netherlands' quality and increase our production, both in terms of batch size and product range."